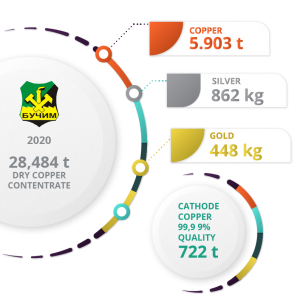

Operational and financial results for 2020

In 2020, Bucim produced 28,484 tonnes of dry copper concentrate, containing 5,903 tonnes of copper, 448 kg of gold, and 862 kg of silver, and produced 722 tonnes of cathode copper of 99.99% quality.

The costs for overhaul activities, maintenance of production plants, and technological equipment reached €3.8 million.

The total value of Bucim’s investment program in 2020, including environmental protection costs was €1.24 million.

Total ESG investments in 2020 reached €472,000.

EBITDA in 220 was €17,593 thousand.

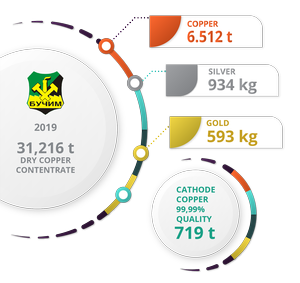

Operational and financial results for 2019

The steady improvement in Bucim’s operational efficiency has resulted in sustainable production volumes.

In 2019, Bucim produced 31,226 tonnes of dry copper concentrate, containing 6,512 tonnes of copper, 593 kg of gold, and 937 kg of silver, and produced 719 tonnes of cathode copper of 99.99% quality.

In 2019, Bucim invested €670 thousand in support of production capacity ( purchases of equipment, machinery, construction, etc.), €130 thousand in health and safety area and €106 thousand in environmental programs. In 2019 Bucim invested €110 thousand in social development. Facility maintenance and repair expenses totaled €4,035 million in 2019.

EBITDA in 2018 was €18,385 thousand.

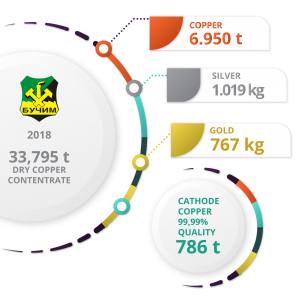

Operational and financial results for 2018

The indicators of the economic success and effectiveness of the operations show that the company has achieved a positive financial result, thereby confirming the success of the operation.

In 2018, Bucim produced 33,795 tonnes of dry copper concentrate, containing 6.950 tonnes of copper, 767 kg of gold, and 1.019 kg of silver, and produced 786 tonnes of cathode copper of 99.99% quality.

In 2018, Bucim invested €830 thousand in the purchases of equipment, infrastructure development, and occupational health and safety (€126 thousand), and environmental protection measures (€101 thousand). Facility maintenance and repair expenses totaled €4,716 thousand in 2018.

EBITDA in 2018 was €22,498 thousand.

Operational and financial results for 2017

Steady improvement of Bucim’s operational efficiency was the key driver ensuring the sustainability of production that resulted in the historically stable performance of the Cu segment of the Group with the 2017 EBITDA margin of 49% at Solway-owned DOO Bucim Radovish, which is North Macedonia’s largest copper mine. The Group’s management is beginning to develop the Borov Dol project which will extend the life of the Bucim mine to 2030. The planned investment in 2018 is US$ 22 million, the majority of which will be funded by committed credit lines provided by local banks.

In 2017, Bucim produced 38,750 tonnes of dry copper concentrate, containing 8,008 tonnes of copper, 975 kg of gold, and 1.094 kg of silver, and produced 958 tonnes of cathode copper of 99.99% quality.

In 2017, Bucim invested €615 thousand in the purchases of equipment, infrastructure development, and occupational health, safety, and environmental protection measures. This included the purchase of dump trucks and drillers, the construction of a diversion channel at the tailing facility and re-cultivation of the tailing dump. Facility maintenance and repair expenses totaled €4,629 thousand in 2017.

EBITDA in 2017 was €26,658 thousand.

Operational and financial results for 2016

Steady improvement of this facility’s operational efficiency was the key driver for ensuring the sustainability of production and for improving financial results at the Solway-owned DOO Bucim Radovish, which is North Macedonia’s largest copper mine.

In 2016, Bucim produced 43,317 tonnes of dry copper concentrate, containing 9,032 tonnes of copper, 664 kg of gold, and 1.343 kg of silver, and produced 1,396 tonnes of cathode copper (Cu) of the 99,99% quality.

In 2016, Bucim invested €678.9 thousand on modernizing its production process, equipment purchases, infrastructure development, and occupational health, safety, and environment protection measures. This included dust recovery at the primary and secondary crushers, reconstruction of the pump station at the cathode production site, construction of a diversion channel at the tailing facility, and a flow-line from the combine to the leaching plant. Facility maintenance and repair expenses totaled €4,267 thousand in 2016.

EBITDA in 2016 €18,945 thousand.